Ideas, Technology and Performances for Concrete Blocks Splitting

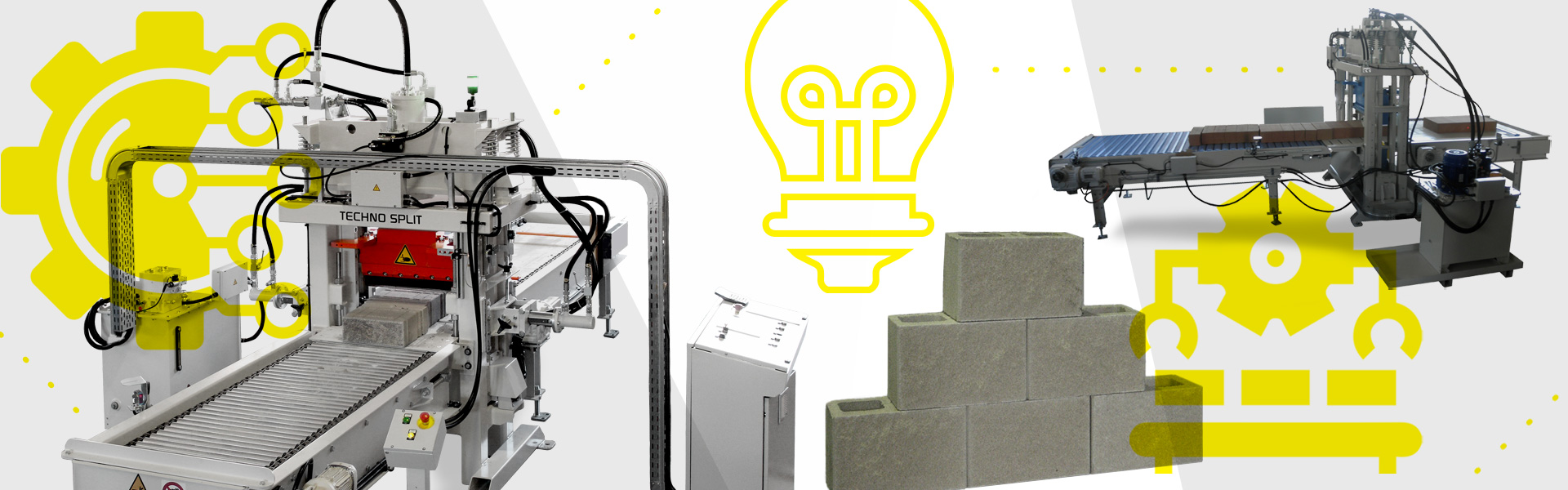

Since 1996 Techno Split, a company based in North Italy, has been designing and building concrete splitting machines and technologically advanced complete and automated concrete splitting lines that can produce a wide range of split products.

Thanks to its expertise, which comes from a good knowledge of the concrete sector and of splitting processes, and to the high quality of its machinery, Techno Split immediately established itself on the global market. It became the European reference point for the largest and best manufacturers of split products in Europe.

With more than 135 concrete splitting machines, the trust of customers, which is considered the company’s most valuable asset, is confirmed over the years. Thanks to a diligent and brilliant work.

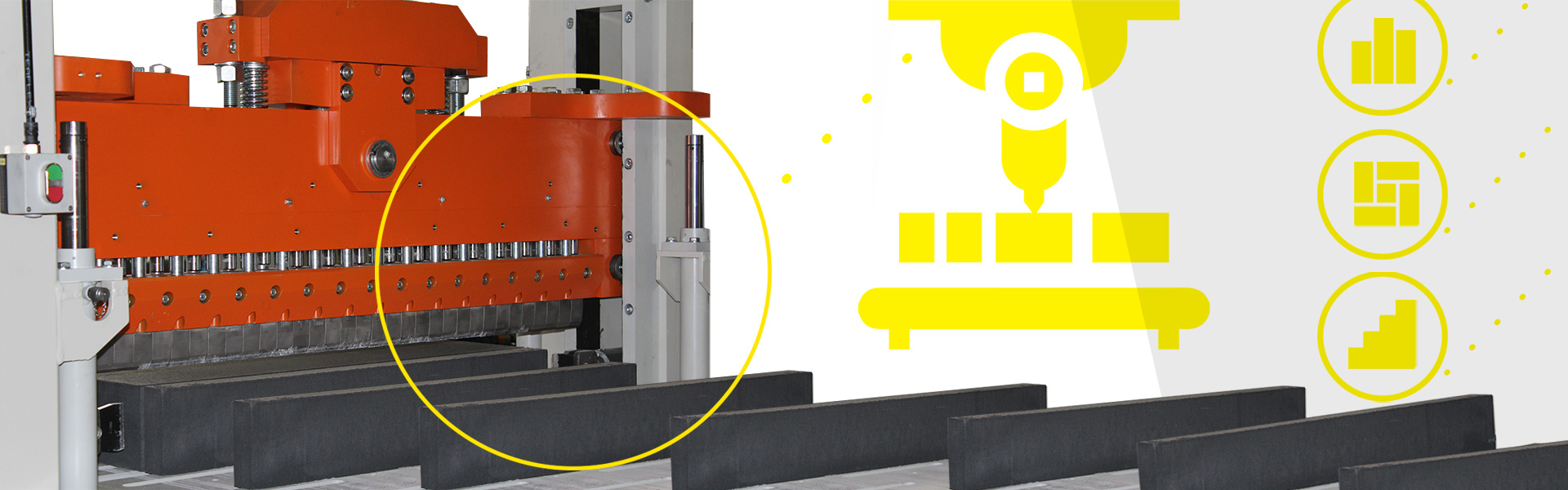

Techno Split designs its own concrete splitting lines using a double structure. The external structure of concrete splitting machine guides the upper blade and allows it descending more precisely and positioning at exactly 90 degrees to the surface of the block. This technology combined with splitting from bottom to top allows a better result of the finished product.

All the control panels of the concrete splitting lines are equipped with remote access so that you can intervene quickly if necessary.

As a precise company choice, the range of concrete splitting lines does not include standard models because the project focuses on attention to the customer’s needs and this allows the most suitable production solution for a perfect optimisation of productivity and investment.

Great importance is given to all the components of the system which is made up of only the best brands on the market. It is able to respect the quality, the precision that this type of processing requires and the availability of spare parts.

Depending on the destination, Techno Split designs its concrete splitting lines issuing a special declaration of conformity to CE or UL standards.

FAQ

Splitting is an industrial production process that consists of dividing or ‘splitting’ concrete blocks to obtain blocks with ‘split’ faces that resemble natural stone.

We design and manufacture both single splitting machines and fully automatic lines.

The typical process includes: loading of the raw blocks by crane, vertical grippers, robots, or automatic palletisers, precise positioning of the blocks to be split under the blade, the splitting phase, evacuation of the technical rejects where applicable, rotation of the blocks if they require a second split, and composition of the finished product row in a suitable position to be picked up and palletised with the chosen unloading system.

To improve splitting we use bottom-up technology, a double structure of the splitting machine that allows the upper and lower blades to be guided with precision, both blades have a system that adapts to the imperfection of the block surface, a pair of side blades that penetrate to the right depth in the block and improve the quality of the artefact.

Split blocks are used in various fields including architecture and are mainly used to embellish a façade, an interior space or a garden. Split blocks are used a lot to build retaining walls, contain an embankment. They are widely used to create the façade of a building, residential fences, ‘Palisaden’ wainscoting, indoor-outdoor walls, steps of an outdoor staircase. In the garden, split blocks are used to create planters, borders.

Yes, we also design and manufacture a wide range of products suitable for concrete block handling operations such as vertical grippers, slewing cranes, robots or automatic palletisers.

All our split systems are designed to last for many years with little maintenance.

Yes. In addition to remote assistance, we can offer maintenance, spare parts, and training for operators.

Yes. For each line, we can provide an EC or UL declaration of conformity, depending on the intended use.

Absolutely. 90% of our installations are built according to the customer’s taste and production requirements. Nevertheless, we also have ‘standard’ models.

Yes, before studying a project we ask a lot of questions and have a dialogue with the customer in order to arrive at a project that meets all the customer’s demands and requirements.

The cost depends very much on the model chosen (size, splitting force, automation, robots, options). Please contact us for personalised advice and a tailor-made quote.

Times may vary depending on the complexity of the project and the customisation required. For a simple project the estimated time is about 3 to 4 months, for very complex projects it can take 6 months.

You can email us at info@technosplit.com.

Follow us