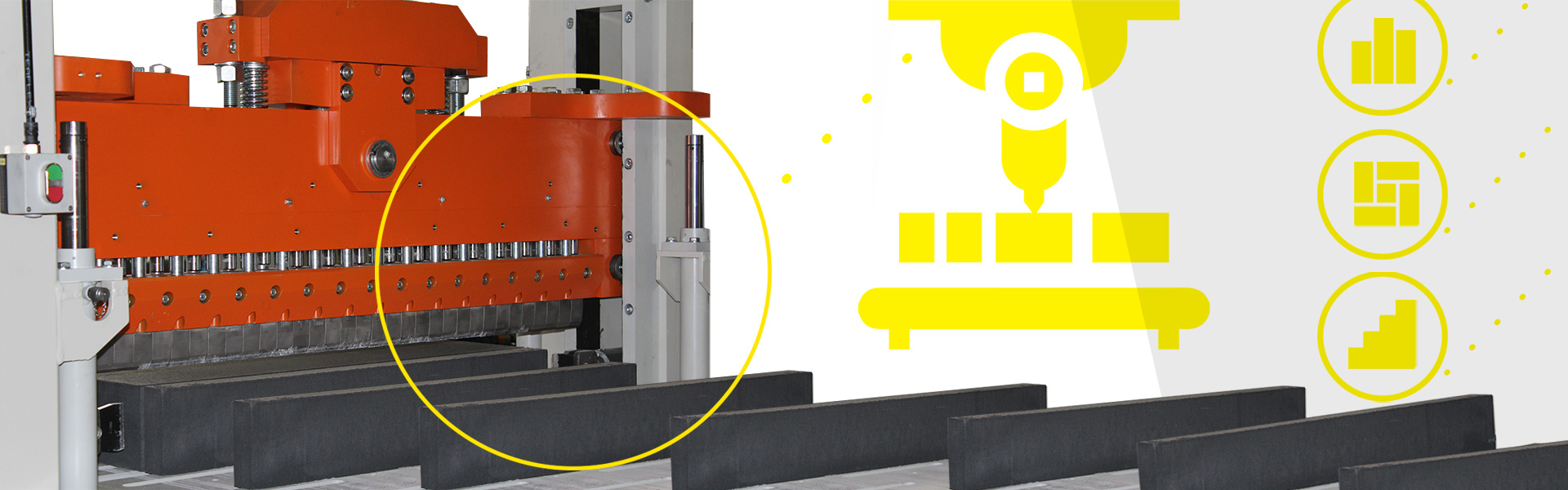

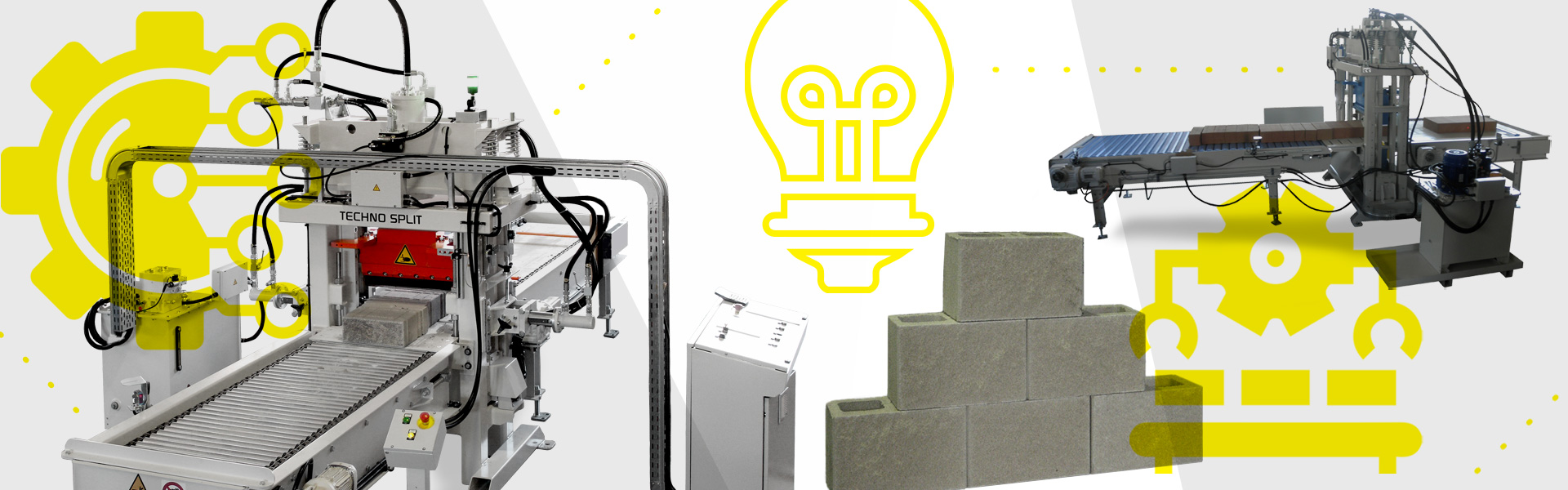

Ideas, Technology and Performances for Concrete Blocks Splitting

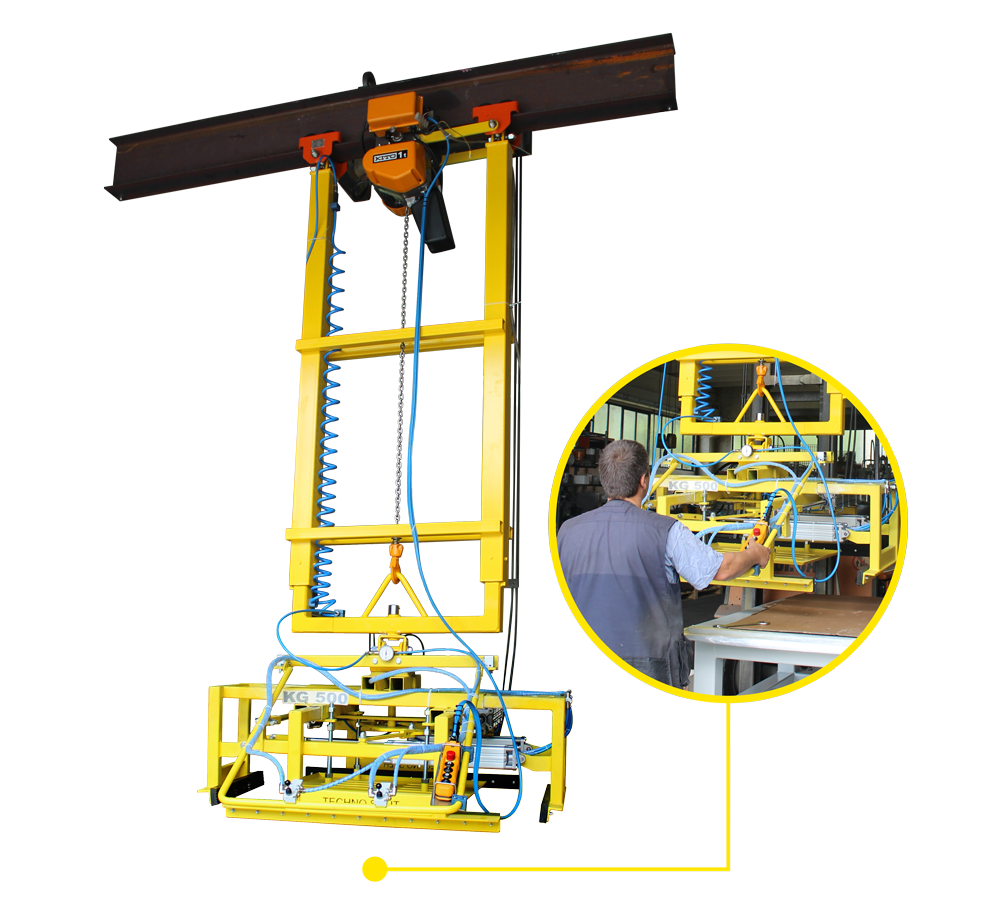

Vertical column gripper

VERTICAL COLUMN GRIPPER FOR CONCRETE PRODUCTS

A modern, well-built and efficient splitting line is not enough to determine the productivity of a splitting system, which needs continuous loading and unloading operations.

Particular attention should also be paid to the way in which to load the blocks that are to be split, then unload and palletize the finished products.

The Techno Split offer has never lacked technical solutions adequately studied and sized according to the type of line proposed to the customer.

Until now, Techno Split’s offer included automatic palletizers with electric closure able to advance 2 metres per second, anthropomorphic robots and jib cranes. Vertical grippers were designed to facilitate, at a low cost, the operations carried out by the latter equipment and are located between automatic palletizers and jib cranes.

The gripper was designed to lift up to 1,000 kg and is equipped with an electric hoist.

The customer can choose between two available travel speeds, 10 or 20 metres per minute, while the lifting speed varies from 7.1 to 1.2 metres per minute with inverter.

The whole vertical system is equipped with a two or four jaw gripper manufactured by Techno Split, carefully designed to be as versatile as possible, and allows both the opening and the height of the gripper to be adjusted so that it can be used on a wide range of products.

Vertical column

gripper

Strong points

Strong points

- Lifting capacity up to 1,000 kg

- Improves and facilitates the handling of concrete products

- Handles both individual blocks and entire rows and/or sets of concrete blocks

- Allows adjustment of the height of the blocks for a customised and secure grip

Follow us