Ideas, Technology and Performances for Concrete Blocks Splitting

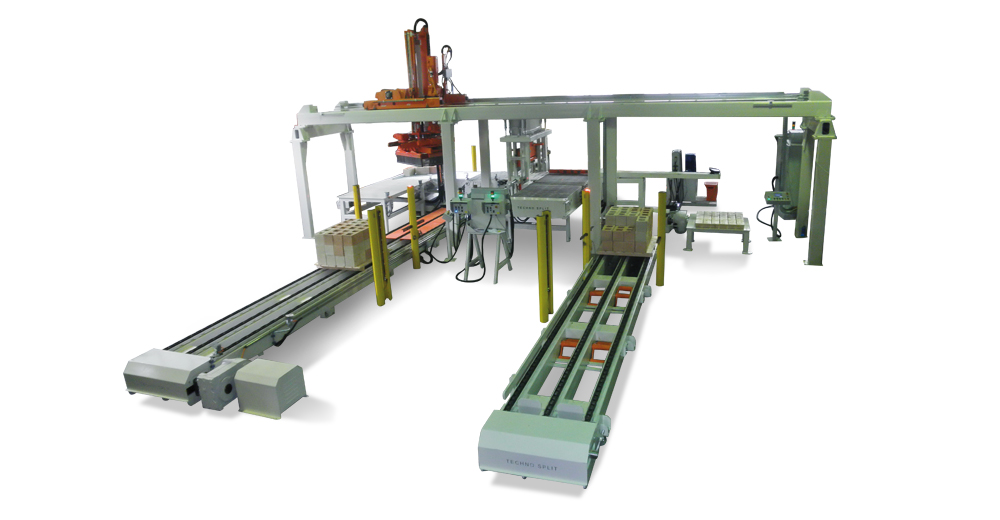

Automatic concrete splitting line and and packaging of concrete blocks TS 120/40 120T

Mod. Split & Pack

AUTOMATIC CONCRETE SPLITTING LINE AND PACKAGING OF CONCRETE BLOCKS

High performance automatic concrete splitting line, sturdy and reliable, it is able to produce large quantities of top quality products.

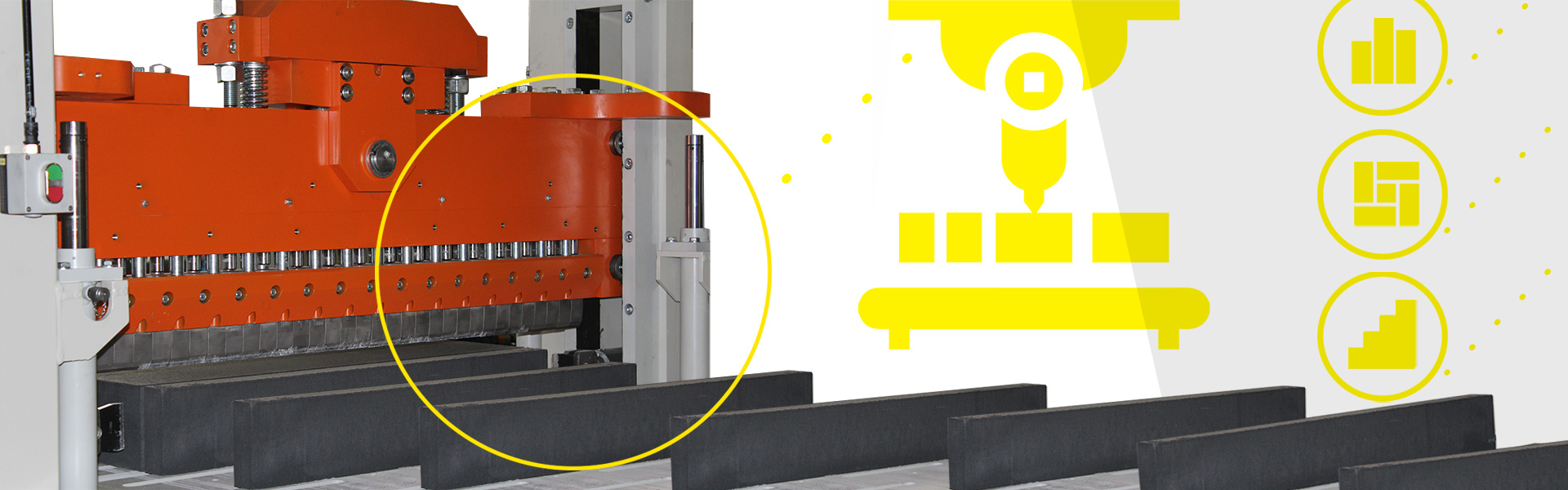

Exclusive Techno Split technology uses two structures on the concrete splitting machine. The external structure allows a more precise guide of the descent of the upper blade and allows the splitting action from bottom to top, offering a significant improvement in the quality of processing.

Loading, unloading, advance of the blocks under the blade, evacuation of technical waste and palletising of finished products are fully automatic.

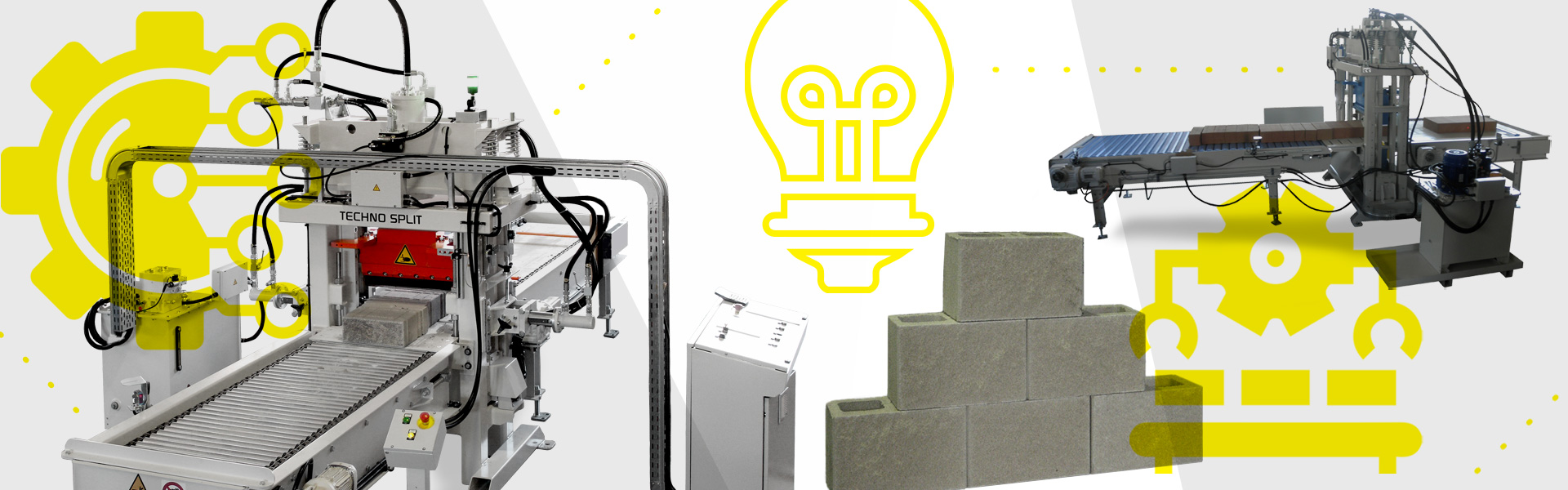

This concrete splitting line has two important new features:

the automatic gripper with electric closing and the possibility of product quality control.

The concrete splitting line is built with only the best components on the market, able to guarantee precision and high performance.

The whole structure is appropriately oversized in order to be long-lasting while optional extras, such as the side blades penetrating the block simultaneously with the upper and lower blade, further improve the quality of the finished product.

Split & Pack

Strong points

Strong points

- Splitting technology from bottom to top to improve processing quality

- Double structure of the concrete splitting machine for a more precise descent of the upper blade

- Automatic loading, unloading, splitting, technical waste evacuation and palletising operations

- Quality control included in the work cycle

- Gripper with high-performance brushless servomotors

- Possibility of customisation in the composition of the line and its options

- High quality of the finished product

- Large quantity of split products

- Brushless servomotors

- Remote assistance

Description of the work cycle of concrete splitting line

Description of the work cycle of concrete splitting line

Once the pallets of blocks to be processed have been positioned on the chain conveyor and brought to the loading area, the gripper picks them up from the pallet one row at a time and loads them onto the inlet conveyor, where a servomotor-controlled pusher pushes the row of blocks under the blade of the hydraulic concrete splitting machine.

Once all the splits envisaged by the recipe have been made, the products pass through the quality control area.

Those to be rejected are automatically evacuated while the others reach the unloading area where the gripper loads them onto pallets.

Concrete Splitting machine technical data

Blade length

mm 1.200

Splitting height

mm 400

Splitting force

Ton 120

→ Finished products ←

Splitted concrete steps

Splitted concrete blocks

for wall cladding

and retaining walls

Splitted Palisaden

Follow us