Ideas, Technology and Performances for Concrete Blocks Splitting

Automatic concrete splitting line TS 136/40 120T

Mod. RMA

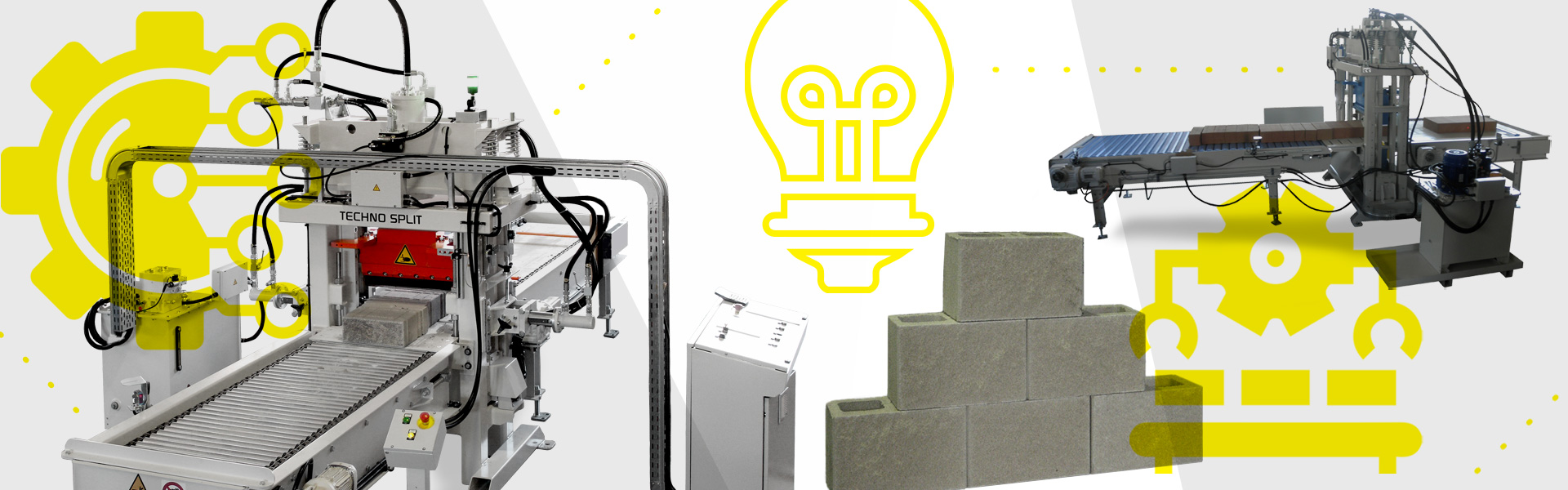

AUTOMATIC CONCRETE SPLITTING LINE

High performance automatic concrete splitting line, sturdy and reliable, it is able to produce large quantities of top quality split concrete splitting machine.

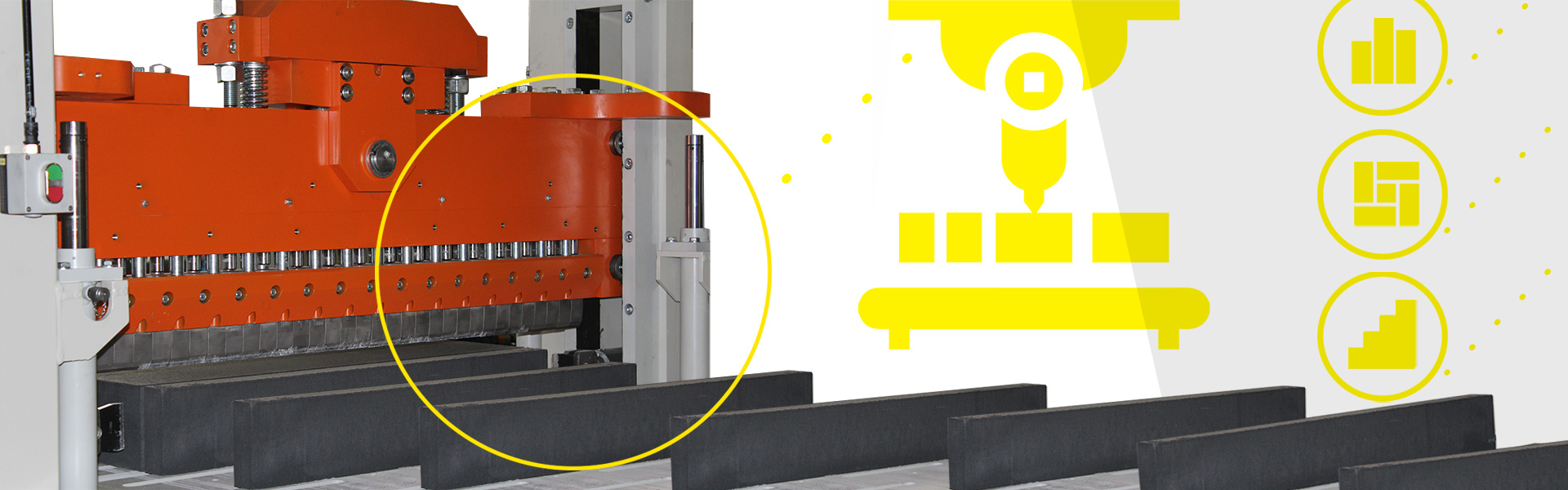

The external structure allows a more precise guide of the descent of the upper blade and allows the splitting action from bottom to top, offering a significant improvement in the quality of processing.

Loading and unloading operations are carried out using vertical grippers made by Techno Split, while the advancement, the positioning of the blocks under the blades of the two concrete splitting machines and the evacuation of technical waste take place automatically after passing through the quality control area.

The concrete splitting line is built with only the best components on the market, able to guarantee precision and high performance.

The whole structure is appropriately oversized in order to be long-lasting while optional extras, such as the side blades penetrating the block simultaneously with the upper and lower blade, further improve the quality of the finished product.

RMA

Strong points

Strong points

- Splitting technology from bottom to top to improve processing quality

- Double structure of the concrete splitting machine for a more precise descent of the upper blade

- Minimum investment

- Automatic and precise work cycle

- Possibility of customisation in the composition of the line and its options

- High quality of the finished product

- Large quantity of split products

- Servomotori Brushless

- Remote assistance

Strong points of the concrete splitting line

- Splitting technology from bottom to top to improve processing quality

- Double structure of the concrete splitting machine for a more precise descent of the upper blade

- Quality control area for the split blocks

- Automatic and precise work cycle including the evacuation of technical waste

- Possibility of customisation in the composition of the concrete slitting line and its options

- High quality of the finished product

- Large quantity of split products

- Brushless servomotors

- Remote assistance

Description of the work cycle of concrete splitting line

Description of the work cycle of concrete splitting line

The blocks are loaded onto the infeed conveyor by vertical cranes manufactured by Techno Split. The pushing bars on the conveyor take the concrete blocks under the blade of the first concrete splitting machine. The program makes all the splits envisaged in the recipe, automatically evacuates the technical waste to the right, positions the products on the conveyors on the left, from which they are taken to the second concrete splitting machine. Once all the splits envisaged in the recipe have been made, the split items pass through an area where quality control is carried out.

Blocks that are not considered first choice are evacuated and taken out of the working area. Blocks that are considered suitable are pushed with the aid of a pusher onto the last conveyor which allows correct positioning for easy unloading of the products by means of a second vertical gripper.

Each concrete splitting machine in the line comprises:

- A sensor that controls the blade penetration during the splitting phase.

- A system that facilitates the locking and unlocking of the blade tools.

- A gear motor in place of the manual handwheel that motorises and optimises the adjustment of the height of the side blades of the concrete splitting machine

- A proportional valve with variable flow rate was fitted on the hydraulic control unit of each machine, as well as the oil cooling and heating system with weekly operation programming.

1st concrete splitting machine technical data

Blade length

mm 1360

Splitting height

mm 400

Splitting force

Ton 120

2nd concrete splitting machine technical data

Blade length

mm 800

Splitting height

mm 400

Splitting force

Ton 90

→ Finished products ←

Steps

Blocks for wall cladding and retaining walls

Fencing

Follow us